Volkswagen has resumed assembling cars in Thika, Kenya, aiming to boost the local auto industry, create jobs, and offer more affordable vehicles. The plant focuses on producing the Polo Vivo sedan using parts imported from South Africa, with an initial target of 1,000 units annually, scaling to 5,000. This move supports Kenya’s industrial goals, strengthens ties with Germany, and provides opportunities for local suppliers and workers to gain advanced skills. Challenges include competition from used car imports, high production costs, and limited local suppliers, but Volkswagen’s investment signals confidence in Kenya’s potential as a regional automotive hub.

Volkswagen‘s Background in Kenya

New Investment and Government Support

Volkswagen’s re-entry into Thika has been significantly supported by the Kenyan government. Through specific policy changes and incentives, the government has created an environment that encourages long-term success for automotive ventures.

Collaboration with Kenya Vehicle Manufacturers

Partnering with Kenya Vehicle Manufacturers has been a key move for Volkswagen. This local collaboration brings valuable regional knowledge, helping ensure that their operations align with both market demands and regulatory standards. Together, these efforts set the stage for efficient assembly operations in the region.

Assembly Operations Details

Vehicle Models and Production Numbers

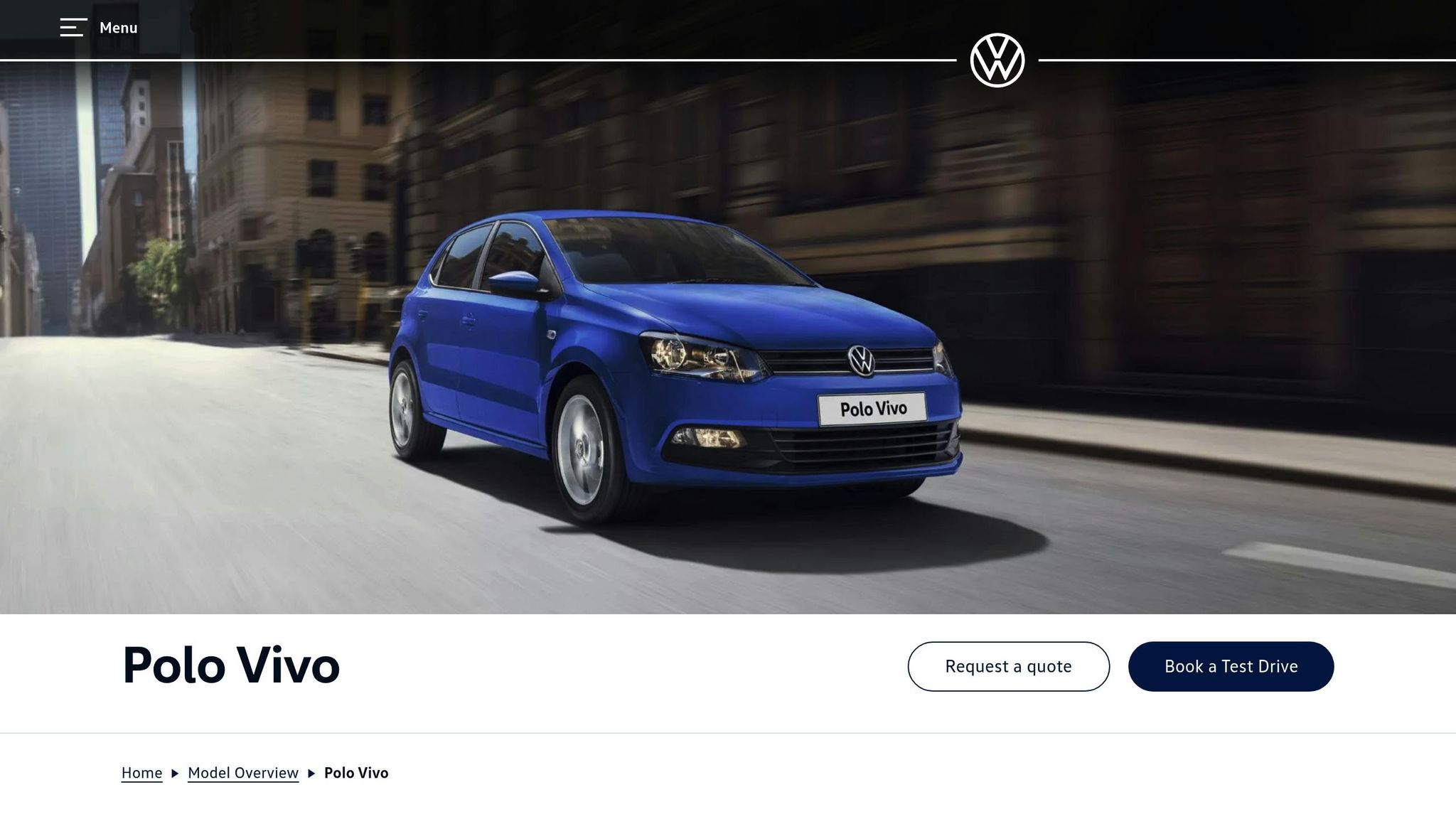

The Thika assembly plant has resumed operations with a focus on assembling the Polo Vivo family saloon, a compact sedan. This model is built using complete knock-down (CKD) kits imported directly from Volkswagen’s Uitenhage manufacturing facility in South Africa.

Initially, the plant is producing 1,000 vehicles annually, with plans to scale up to 5,000 units per year. This increased capacity highlights the plant’s growing role in Kenya’s automotive manufacturing sector. By utilizing a Level 2 CKD process, the facility ensures high-quality standards while promoting local assembly efforts.

These production goals aim to drive economic growth and expand employment opportunities in the region.

Investment Amount and Jobs Created

While specific investment figures remain undisclosed, the August 2025 restart demonstrates Volkswagen’s strong commitment to Kenya’s automotive industry.

The project’s impact extends far beyond the assembly line. Arvinder Reel, Managing Director of CFAO Mobility Kenya, emphasized the broader benefits:

"Through our investment at KVM, we are providing more job opportunities to Kenyans, offering innovation and skills transfer from global OEMs, supporting growth of SMEs through local content input, and availing even more affordable vehicles to the Kenyan consumer."

The upgraded Kenya Vehicle Manufacturers facility now supports a diverse production lineup, including Mercedes-Benz trucks, Tata units, Hyundai vehicles, Sinotruk models, and electric buses from BasiGo. This variety not only stabilizes employment but also maximizes the plant’s operational potential.

The investment fuels immediate job creation while also enhancing Kenya’s industrial base, paving the way for long-term technology transfer and economic development.

Technology Transfer and Local Suppliers

Volkswagen’s strategy goes beyond vehicle assembly, focusing on technology transfer and the development of local suppliers. This initiative is designed to integrate small and mid-sized parts suppliers into the automotive value chain, creating new opportunities for local businesses.

Deputy Ambassador Alexander Fierley highlighted this cooperation:

"Our renewed cooperation with Kenya seeks to build stronger linkages between our industries, foster innovation and technology transfer, while supporting the country’s economic ambitions."

Manas D., Director of Global Exports at Kraftsgroup, further explained the importance of building local capabilities:

"The success of a major assembly plant like this is always amplified by the strength of its aftermarket ecosystem. It creates a long-term, sustainable demand for a world-class supply of certified spare parts and high-performance lubricants to service these new vehicles. This is a powerful opportunity for strategic partnerships to build that robust local value chain."

Economic and Job Benefits

Direct and Indirect Job Creation

CFAO Mobility Kenya recently announced job openings for Assembly Technicians, Logistics Technicians, and Quality Inspectors, with applications closing on September 8, 2025. These roles represent the initial steps in a broader effort to expand employment opportunities within the region.

Beyond these direct jobs, the initiative is poised to generate numerous indirect roles across the automotive supply chain. Small and mid-sized parts suppliers stand to gain significantly, as renewed Kenya–Germany cooperation introduces advanced assembly techniques, cutting-edge technology, and specialized training. This kind of knowledge transfer is expected to create a ripple effect, with trained technicians driving growth across the industry.

These employment opportunities are not just about jobs – they’re a key driver for Thika’s economic development.

Economic Growth in Thika and Kenya

The benefits of Volkswagen’s expanded operations go beyond employment. The facility’s activities contribute to Thika’s industrial ecosystem, strengthening its role as a hub for diversified production. This expansion supports local industries and enhances the region’s economic resilience.

CFAO Mobility Kenya’s leadership highlighted their commitment to this vision:

"Through our investment at KVM, we are driving growth in local assembly, empowering SMEs and enabling access to affordable world‑class mobility solutions for the Kenyan market."

The facility’s operations create a ripple effect, benefiting local suppliers, logistics firms, and service providers. This interconnected growth helps stabilize jobs and lays a stronger foundation for Thika’s economy.

Benefits vs Challenges Analysis

While the initiative brings clear advantages, it also faces significant challenges within the local market. Here’s a closer look at both sides:

| Benefits | Challenges |

|---|---|

| Creation of direct jobs in assembly, logistics, and quality control | High reliance on used car imports, which diminishes demand for locally assembled vehicles |

| Transfer of advanced skills and technology to Kenyan workers | Expensive electricity and dependence on imported components drive up production costs |

| Support for SMEs through local supplier integration and parts sourcing | Limited local supplier base increases vulnerability to supply chain disruptions |

| Contribution to Kenya’s industrialization and economic diversification | Weak enforcement of vehicle age restrictions undermines government efforts to support local assembly |

| Low consumer purchasing power and high interest rates limit demand for new vehicles | |

| Non‑tariff barriers within the East African Community and competition from other African manufacturing hubs |

Overcoming these hurdles will be essential for the success of the project. The dominance of cheaper used car imports, in particular, threatens to undercut the plant’s efficiency and raise production costs. To unlock the full potential of Volkswagen’s renewed operations in Thika, sustained government support – through stronger policy enforcement and infrastructure investment – will be vital.

sbb-itb-e5ed0ed

Effects on Kenya’s Car Market

Price Changes and Vehicle Access

Local assembly of vehicles in Kenya is reshaping the market by reducing import duties and shipping costs. This narrowing of the price gap between new and imported cars makes new models more accessible to buyers. For those seeking new vehicles, this shift also means quicker delivery times and the assurance of verified warranties. These pricing changes not only benefit buyers but also open doors to improved services and environmental advancements. Ultimately, the final pricing will depend on market forces and the implementation of supportive policies.

Customer Service and Market Support

Producing cars locally simplifies the supply chain for spare parts and enhances after-sales services. This includes better access to components and more efficient maintenance processes. Additionally, Volkswagen’s direct involvement in training local service technicians ensures higher-quality repairs and upkeep. These developments stand to benefit not just individual car owners but also businesses that depend on reliable vehicle fleets. Improved service and operational efficiency align with Kenya’s broader efforts to adopt more sustainable practices.

Green Transportation and Government Policy

Local vehicle assembly is a step toward promoting greener transportation and sustainable growth in Kenya. New Volkswagen models built in Thika incorporate advanced engine technologies and emission control systems, which help reduce environmental impact. Government incentives, such as tax breaks and skills development programs, further encourage local manufacturing. However, the success of these efforts relies heavily on consistent policy enforcement and ongoing support for the local automotive industry.

Volkswagen Polo Vivo assembly in Thika

Conclusion: Kenya’s Automotive Future

Volkswagen’s return to Thika signals a major shift for Kenya’s automotive industry, paving the way for industrial growth and making vehicle ownership more achievable for many. This move not only strengthens Volkswagen’s presence in the region but also sparks broader industrial changes that could transform Kenya’s economy.

The impact reaches far beyond the factory floor. New jobs – both direct and indirect – boost Kenya’s manufacturing sector while fostering technical skills that can fuel other industries. This ripple effect supports various related businesses, creating a stable foundation for long-term economic growth.

For Kenyan consumers, the benefits are just as impactful. By eliminating import duties and shipping costs, locally assembled vehicles become more affordable, opening up access to a wider audience. Improved service networks make car ownership more reliable and cost-efficient, which is especially valuable for businesses relying on vehicle fleets for daily operations.

On top of the economic and consumer advantages, there’s an environmental win. Locally assembled vehicles often feature modern emission-reduction technologies and fuel-efficient engines, aligning with Kenya’s sustainability goals. These advancements not only support a cleaner environment but also help reshape the automotive market toward a greener future.

Volkswagen’s success in Thika could also attract other automotive manufacturers to Kenya. This potential wave of investments would foster healthy competition, spark innovation, and further establish Kenya as a hub for automotive manufacturing in East Africa. With improved access to vehicles, better service, and a focus on sustainability, Kenya’s automotive future looks both economically strong and environmentally conscious.

FAQs

What challenges is Volkswagen facing in restarting its assembly operations in Thika, and how might they address them?

Volkswagen is facing a range of hurdles as it resumes its assembly operations in Thika. Among the main challenges are delays in rolling out automotive policies, a lack of clarity in regulatory frameworks, and infrastructure constraints in Kenya. These factors could potentially hinder their progress and disrupt operational efficiency.

To navigate these challenges, Volkswagen will likely collaborate with the Kenyan government to push for clearer, more supportive policies. The company might also consider investing in infrastructure improvements and tailoring its production to meet the unique demands of the Kenyan market. By taking these steps, Volkswagen aims to solidify its presence in the region while contributing meaningfully to the local economy.

How will Volkswagen’s local assembly in Thika make new vehicles more affordable and accessible for consumers in Kenya?

Volkswagen’s move to revive local assembly operations in Thika brings a significant advantage to Kenyan consumers by making new vehicles more affordable. By assembling cars locally, the company reduces import taxes and shipping fees, which directly lowers the cost of vehicles. This makes it possible for more people in Kenya to own new cars without stretching their budgets.

Beyond affordability, the local assembly plant provides a boost to the Kenyan economy. It creates job opportunities and supports related industries, which can lead to higher household incomes. With more people employed, families may find it easier to access reliable transportation. Plus, a stronger local workforce contributes to reducing overall transportation costs, benefiting the wider community. This approach reflects a thoughtful response to the needs of the Kenyan market, offering more people access to dependable and reasonably priced mobility solutions.

How does Volkswagen’s investment in Thika support the growth of Kenya’s automotive industry and economy?

Volkswagen’s move to resume vehicle assembly in Thika is a significant step forward for Kenya’s automotive sector and its economy. By bringing back modern assembly processes, the company is not only introducing advanced technology but also encouraging new ideas and practices. This positions Kenya as a potential leader in the region’s automotive market.

The investment goes beyond just assembling cars – it generates new jobs and strengthens local supply chains, which fuels economic progress. It also helps develop specialized skills in automotive manufacturing, setting the stage for long-term industrial growth and making vehicles more accessible to Kenyan consumers.

Related Blog Posts

- Top 5 Automotive Trade Fairs in Kenya 2025

- Most sold cars in Kenya this year

- Toyota vs Nissan in Kenya: Which One Should You Choose?

- Kenya opens East Africa’s first EV battery lab in Nairobi